Lean Six Sigma Black Belt Training Overview

Lean Six Sigma Black Belt Training (LSSBB) is designed for professionals aspiring to excel in the quality sector. This comprehensive course equips individuals to lead, guide, and actively contribute to Lean Six Sigma projects from inception to completion, making them highly proficient in the domain.

Course Focus

The Lean Six Sigma Black Belt Training covers the entire DMAIC methodology, offering a deep dive into Six Sigma tools and Lean principles. It emphasizes mastering statistical tools and Lean practices essential for process improvement.

Learning Benefits

Participants in Trainerkart’s LSSBB training will benefit in the following ways:

- Gain a solid understanding of Lean Six Sigma concepts.

- Focus extensively on DMAIC, covering every critical aspect.

- Learn to identify improvement projects and measure processes effectively.

- Acquire skills in data analysis, hypothesis testing, and performance improvement actions.

- Utilize DFSS tools like QFD, FMEA, and RPN for efficient decision-making.

- Enhance process control using Lean tools and DOE.

Career Growth Opportunities

Earning certification as a Lean Six Sigma Black Belt professional presents remarkable career prospects:

- Career Growth: Propel your career with practical exposure to Lean Six Sigma tools, enabling a consistent upward trajectory.

- Salary Potential: Indeed.com reports a national average salary of $80,000 per year for Certified Black Belts in the United States.

- Diverse Roles: Unlock opportunities in roles such as Quality Manager, Quality Analyst, Lean Consultant, Quality Assurance, and Quality Control across various industries.

Top companies like GE, AlliedSignal Corporation, McKesson Corporation, 3M, AXA, Cognizant Technology Solutions, Ford Motor Company, Glaxo SmithKline, Honeywell, HSBC Group, Motorola, Wipro, Xerox, and many more have invested in implementing Lean Six Sigma concepts. Thereby, they have increased the number of opportunities for Lean Six Sigma certified professionals.

We also provide training in many other courses under Quality Management.

Join us on social media platforms— Facebook, Twitter, LinkedIn, Google+, YouTube – to share your experience with our Lean Six Sigma Green Belt Training.

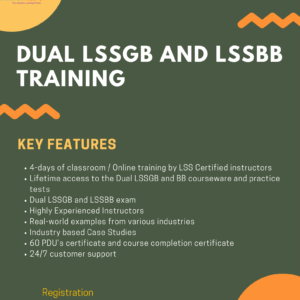

Lean Six Sigma Black Belt Training – Key Features

- 32 Hours of Instructor Led Training

- 100% Money Back Guarantee*

- Free 90 Days e-learning access

- Attend multiple batches with flexible time slots within 90 days

- Exclusively designed for working professionals

- Real world examples from various industries

- 35 PDUs Offered

- LSSBB Simulation Exams

- Collection of six sigma tools for hands-on practice

- Industry based case studies

FAQ

Is Minitab installation necessary before starting the course?

No, Minitab installation is not required to begin the LSSBB course by Trainerkart.

Will I receive Excel sheet templates if I do not have Minitab installed?

Yes, we provide a toolkit in the course package that includes various tools and Excel sheets used in the context of Lean Six Sigma.

How is Trainerkart’s Lean Six Sigma Black Belt Training different from Certified Six Sigma Black Belt Training?

Trainerkart’s Lean Six Sigma Black Belt Training emphasizes Lean Six Sigma methodologies, tools, and techniques. It strongly focuses on understanding Lean principles and integrating them with Six Sigma practices to enhance process efficiency and reduce waste. Our Certification Exam aligns with certifying bodies like ASQ, gaining recognition across industries and holding higher credibility.

Is a project completion necessary for the Lean Six Sigma Black Belt Training?

No, there is no requirement for project completion to finish the Lean Six Sigma Black Belt Training by Trainerkart.

Will I receive a certificate after completing the Lean Six Sigma Black Belt Training?

Upon successful completion of the Lean Six Sigma Black Belt Training with Trainerkart, you will receive a course-completion certificate. Additionally, upon passing our internal Black Belt Certification Exam, you will be awarded the Black Belt Certificate, widely recognized across various industries.

What learning elements are included in this Lean Six Sigma Black Belt Training?

Trainerkart’s Lean Six Sigma Black Belt Training (LSSBB Training) includes:

- Core lessons, with each lesson covering one aspect of DMAIC

- End-of-lesson quizzes

- Real-world examples from various industries

- Case studies covering comprehensive scenarios

- Exclusive versions of Glossary and Acronyms related to Lean Six Sigma

Understanding Lean Six Sigma Black Belt Certification

The Lean Six Sigma Black Belt Certification represents a blend of Lean and Six Sigma methodologies and is granted to professionals who successfully pass the LSSBB exam. Each methodology contributes unique strengths to this comprehensive certification:

- Lean: Lean comprises techniques aimed at reducing time in product delivery. Its focus is on enhancing efficiency and eliminating wasteful processes.

- Six Sigma: Six Sigma is a disciplined approach focused on improving product and service quality, ensuring consistent and exceptional delivery. It emphasizes error reduction and maintaining high standards.

Lean Six Sigma Approach: Achieving Perfection

The Lean Six Sigma approach integrates both Lean and Six Sigma methodologies, striving for service improvement within specified timeframes while eliminating defects. This approach guides projects towards perfection, enhancing efficiency and efficacy.

The Value of Lean Six Sigma

Lean Six Sigma has gained widespread popularity as a business management strategy adopted in projects globally. Its application significantly aids organizations in achieving process excellence, ultimately resulting in heightened profitability.

Benefits of Lean Six Sigma Black Belt Certification

Obtaining a Lean Six Sigma Black Belt certification signifies an individual’s proficiency in deploying skills across enterprise-wide projects. It showcases their capability to take on full-time roles dedicated to process excellence, highlighting their expertise in driving organizational improvements.

Exam And Certification

To become a Certified Lean Six Sigma Black Belt through Trainerkart:

- The certification exam is part of our training package.

- The online exam comprises 100 multiple choice questions with a 120-minute duration.

- A minimum score of 70% is required to obtain the certificate.

- No negative marking for wrong answers.

- Current Pass Rate: 98%

For IASSC or ASQ Certification, the third-party exam fee is not included in our courses.

IASSC or ASQ Certification:

Third party Exam Fee is not included in our courses.

What are the prerequisites for the certification?

A basic understanding of Lean and Six Sigma tools is required, with additional working knowledge of the DMAIC approach being advantageous.

How does the refund process work?

For more details on the refund process, please visit our Refund Policy and Cancellation Policy. (*Under Terms and Conditions)

Course Agenda: Lean Six Sigma Black Belt

-

Introduction

- A Brief History of Quality

- Understanding Quality: Products and Services Definitions

- Quality Gurus and Their Contributions

- Enterprise-wide View

- Leadership in Quality

- Roles and Responsibilities in Six Sigma

- Team Formation and Dynamics

- Team Facilitation

- Effective Team Dynamics

- Time Management for Teams

- Team Decision-making Tools

- Management and Planning Tools

- Team Performance Evaluation and Rewards

- Overview of DMAIC

-

Define

- Identifying Important Stakeholders

- Assessing Impact on Stakeholders

- Critical-to-X (CTQ) Requirements

- Benchmarking

- Business Performance Measures

- Financial Metrics for Projects

- Voice of the Customer (VOC)

- Kano’s Customer Satisfaction Levels

- Juran’s Customer Needs

- Market Research Techniques

- CTQ Flow down Strategies

- Quality Function Deployment (QFD)

- Performance Metrics

- Project Charter and Negotiation

- Project Management Plan and Baselines

- Project Tracking

-

Measure

- Understanding Processes, Characteristics, and Flow Metrics

- Process Maps and Flowcharts

- SIPOC (Supplier, Input, Process, Output, Customer)

- Data Types and Measurement Scales

- Data Collection Techniques

- Sampling Strategies

- Fishbone Diagram

- Relational Matrices and Prioritization

- Basic Statistics

- Analytical Statistics

- Gauge R & R (Repeatability and Reproducibility)

- Process Capability Analysis

-

Analyze

- Correlation and Regression Analysis

- Testing Hypotheses

- Failure Mode and Effects Analysis (FMEA)

- Gap Analysis

- The Five Whys Technique

- Pareto Diagram

- Tree Diagram

- Identifying Non-Value-Added Activities

- Cost of Poor Quality (COPQ)

-

Improve

- Design of Experiments (DOE)

- Poka-yoke (Mistake-proofing)

- 5S (Sort, Set in Order, Shine, Standardize, Sustain)

- Kanban

- Standard Operations and Work Instructions

- Cycle Time Reduction and Takt Time

- Continuous Flow Manufacturing

- Single-Minute Exchange of Die (SMED)

- Kaizen and Kaizen Blitz

- Theory of Constraints (TOC)

- Risk Analysis

-

Control

- Statistical Process Control (SPC)

- Other Control Tools

- Maintenance of Controls

- Sustaining Improvements

-

DFSS

- Design for Six Sigma (DFSS)

-

More on Lean

- Value Stream Mapping

- Lean Principles: Speed and Efficiency

- Total Supply Chain Considerations

- Lean Six Sigma Logistics

-

Case Studies

- Case Study 1:

- Part 1

- Part 2

- Case Study 2:

- Part 1

- Part 2

Reviews

There are no reviews yet.