Dual LSSGB and LSSBB Training Course Overview

Trainerkart’s Dual Lean Six Sigma Green Belt and Black Belt Training course is a comprehensive learning experience designed to empower individuals in implementing a continuous improvement process within organizations. Our course is thoughtfully crafted, with the course material and practice exam questions developed by global experts and industry leaders. The curriculum is structured around lean methodologies and the DMAIC (Define, Measure, Analyze, Improve, Control) process, the core tool for driving Six Sigma projects and achieving a high level of quality by eliminating defects and reducing waste.

Please fill in the inquiry form on this page or call now on +1 (281) 810 – 9891 or e-mail info@trainerkart.com for our training consultant to understand your training and learning objectives and guide you with an optimum way to achieve your goals.

We also provide training many project management courses under the project management category.

Join us on social media platforms— Facebook, Twitter, LinkedIn, Google+, YouTube – to share your experience with our Dual LSSGB and LSSBB Training.

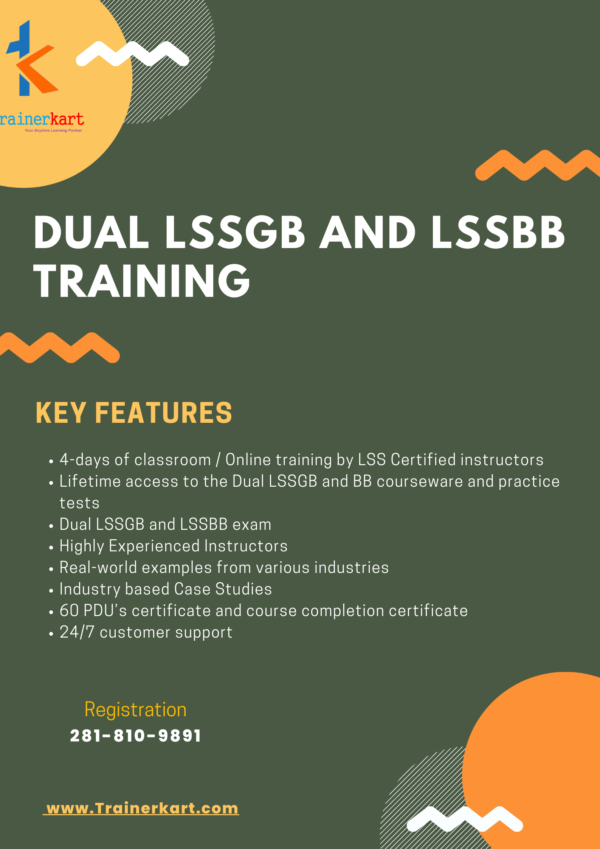

Dual LSSGB and LSSBB Training – Key Features

- 4-days of classroom / Online training by LSS Certified instructors

- Lifetime access to the Dual LSSGB and BB courseware and practice tests

- Dual LSSGB and LSSBB exam

- Highly Experienced Instructors

- Real-world examples from various industries

- Industry based Case Studies

- 60 PDU’s certificate and course completion certificate

- 24/7 customer support

Benefits of Dual Lean Six Sigma Training

The Dual Lean Six Sigma Green and Black Belt training program distinguish themselves by offering significant benefits to professionals aspiring to excel in the quality sector:

- Enhanced Skill Set: Attain a comprehensive skill set, enabling the effective management and leadership of complex projects, covering both Lean and Six Sigma methodologies.

- Improved Leadership Abilities: Develop robust leadership skills that empower efficient project management, leading to streamlined processes and optimized resource utilization.

- Market Relevance: Attain dual certifications, enhancing your marketability and meeting the high demand for certified Lean Six Sigma professionals.

- Process Optimization: Learn to map and analyze performance using various Lean Six Sigma tools, enabling the identification of areas for improvement and effective process optimization.

- Cost and Time Efficiency: Acquire the ability to manage projects with minimal expenditure of time and money, contributing to overall cost savings and efficient project delivery.

- Quality Enhancement: Improve organizational performance by minimizing variances and ensuring consistent quality in product/service delivery.

Learning Objectives of Dual Lean Six Sigma Training

The Dual Lean Six Sigma Green and Black Belt training program are structured to achieve the following learning objectives:

- Comprehensive Understanding: Grasp a thorough understanding of Lean and Six Sigma methodologies, roles, responsibilities, and the DMAIC approach.

- Stakeholder Identification and Analysis: Learn to identify and analyze important stakeholders, understanding their impact on projects and quality outcomes.

- Project Selection and Metrics: Gain insights into selecting projects, defining critical metrics, and using financial criteria to evaluate project benefits for optimal results.

- Effective Process Measurement: Understand various data collection techniques, measurement scales, and statistical analysis methods to measure and analyze processes effectively.

- Problem Analysis and Solution Design: Develop skills to perform data analysis, hypothesis testing, and identify improvement actions to enhance process performance and minimize variations.

- Process Control and Sustainability: Learn to define efficient operating levels for inputs and outputs, implement control plans, and sustain process improvements for long-term success.

- Utilization of Lean Tools: Master the use of Lean tools for process control, continuous improvement, and achieving efficient operations.

Achieving these learning objectives equips participants with the knowledge and skills necessary to excel as certified Lean Six Sigma Green and Black Belt professionals, making a positive impact on both projects and organizational performance.

FAQ: Dual Lean Six Sigma Green and Black Belt Training

1. How can I take the exam?

To take the exam, simply email support@trainerkart.com to request login credentials for Trainerkart’s Dual Lean Six Sigma Green and Black Belt online open-book exam. The exam remains valid for seven days with three attempts. After scoring 70% or higher, send a screenshot to support@trainerkart.com. Your Dual Lean Six Sigma Green and Black Belt certificate will be emailed to your registered email address within 2 working days of passing the online exam.

2. Is there a 100% Money Back guarantee?

Yes, we offer a 100% money-back guarantee on Dual LSSGB and LSSBB training. For more details on our Money Back guarantee, please visit our Terms and Conditions page.

3. Are the exam fees included in the course fee?

Yes, the exam fees for Dual LSSGB and LSSBB are included in the course. Please note that the upgrade to third-party exams like ASQ and IASSC exams is not available for the Dual Lean Six Sigma Certification.

4. What type of course completion certificate will I receive?

Upon completing 4 days of In-person/online training, you will receive a 60 PDU certificate. These PDUs can be used to maintain your PMI credentials, including PMP, CAPM, PMI-ACP, PMI-PBA, PgMP, and more.

5. How long can I access the course material?

All registered participants will receive a link to download the courseware. Once downloaded, you will have lifetime single-user access to the Trainerkart course material.

6. Will there be assistance with the exam booking process?

Yes, for the online Dual LSSGB and LSSBB exams, please email support@trainerkart.com, and we will provide you with the online exam login credentials.

7. What distinguishes In-person from live online classrooms?

Both In-person and live online classrooms offer a similar learning experience, except for the physical presence of the instructor and fellow students in In-person classrooms. In live online classrooms, you can interact with the instructor through video, audio, and chat.

8. When will I receive course location and other details?

A course confirmation email will be sent immediately after registration. Additional information such as location, courseware access, instructor contact, timings, guidelines, and more will be shared five days before the class by our training team.

9. Can I cancel or reschedule my enrollment?

Absolutely. To cancel or reschedule your enrollment, email support@trainerkart.com with your request. Depending on the timing of your refund or rescheduling request, a fee may apply. Please refer to our refund policy for more details.

10. How does Trainerkart ensure practicality in the courseware and training?

Our certification training programs are structured to enable you to pass the exam on the first attempt. With a hands-on learning approach, our training program enhances your confidence not only to pass the exam but also to retain knowledge beyond the classroom.

Prerequisites:

There are no prerequisites to attending the training course. However, to appear for the Trainerkart’s Dual Lean Six Sigma Green and Black Belt exam, you need to enroll in either of the three training types offered by us.

To appear for the Dual Lean Six Sigma Green and Black Belt exam, you should either attend:

- In-Person Classroom Training

- Virtual Online Training

- Virtual Online – Weekend Training

- Self-Study training

- Onsite Training Program

We will provide 60 professional development units(PDU’s) along with the course completion certificate upon completion of the training mentioned above.

Exam And Certification:

Dual LSSGB and LSSBB Training Exam and Certification

Exam And Certification

To become a Certified Dual Lean Six Sigma LSSGB and LSSBB through Trainerkart:

- The certification exam is part of our training package.

- The online exam comprises 100 multiple choice questions with a 180-minute duration.

- A minimum score of 70% is required to obtain the certificate.

- No negative marking for wrong answers.

- Current Pass Rate: 98%

For IASSC or ASQ Certification, the third-party exam fee is not included in our courses.

IASSC or ASQ Certification:

Third party Exam Fee is not included in our courses.

What are the prerequisites for the certification?

A basic understanding of Lean and Six Sigma tools is required, with additional working knowledge of the DMAIC approach being advantageous.

Examination Format:

*Questions: 100

* Duration: 3 hours

*Pass Score: 70 percentile

*Exam Type: Open Book

Voucher Validity:

Trainerkart’s Dual LSSGB and LSSBB exam vouchers come with a validity of 12 months. Post the duration you will have to buy the voucher at an additional charge.

Course Agenda:

Dual LSSGB and LSBB Training Agenda

| Day | Lesson No. | Topics |

| Day – 1 | Overview of Lean and Six Sigma | |

| Organizational Objective | ||

| Introduction, Deliverables, and Benefits of Lean Six Sigma Yellow Belt | ||

| Introduction, Deliverables, and Benefits of Lean Six Sigma Green Belt | ||

| Introduction, Deliverables, Benefits of Lean Six Sigma Black Belt | ||

| Profit | ||

| Course Overview | ||

| 1 | Define | |

| 1.1 | Six Sigma: The Basics | |

| The Meaning of Six Sigma | ||

| Problem-solving strategy | ||

| History of Six Sigma and Continuous Improvement | ||

| Roles and Responsibilities | ||

| Project Team Selection | ||

| 1.2 | Six Sigma: The Fundamentals | |

| Voice of Customer | ||

| Critical to Quality (CTQ) | ||

| Affinity Diagrams & Pareto Analysis (80:20) | ||

| Cost of Poor Quality | ||

| Six Sigma Projects: DMAIC | ||

| Basic Six Sigma Matrix | ||

| 1.3 | Project Management | |

| Change | ||

| Project Management Basics | ||

| Business Case and Project Charter | ||

| Cost Benefit Analysis | ||

| Project Risk Management | ||

| Failure Mode & Effects Analysis (FMEA) | ||

| Day – 2 | 1.4 | Lean |

| Understanding Lean | ||

| Lean: History | ||

| Lean vs 7 Deadly Wastes | ||

| Lean and Six Sigma | ||

| 2 | Measure | |

| 2.1 | Process Definition | |

| Process Mapping, SIPOC, Value Stream Map | ||

| XY Matrix | ||

| 2.2 | Six Sigma Statistics | |

| Basic Statistics | ||

| Descriptive Statistics | ||

| Distribution and Normality | ||

| Graphical Analysis | ||

| 2.3 | Measurement System Analysis | |

| Precision & Accuracy | ||

| Accuracy: BIAS, Linearity & Stability | ||

| Variable MSA: GRR | ||

| Stability | ||

| 2.4 | Process Capability | |

| Capability Analysis | ||

| Attribute and Discrete Capabilities | ||

| Day – 3 | 3 | Analyze |

| 3.1 | Patterns of Variation | |

| MultiVari Analysis | ||

| Classes of Distributions | ||

| 3.2 | Inferential Statistics | |

| Understanding Inference | ||

| Sampling Techniques and Uses | ||

| 3.3 | Hypothesis Testing | |

| General concepts and goals of Hypothesis testing | ||

| Significance Practical vs Statistical | ||

| Risk: Alpha & Beta | ||

| Hypothesis Testing | ||

| Reading tables | ||

| Excel: Data Analysis ToolPak | ||

| Testing from Normality | ||

| 3.4 | Hypothesis Testing with Normal Data | |

| Test of Equal Variance | ||

| Z Tests | ||

| 1 Sample T Test | ||

| 2 Sample T Test | ||

| Sample Variance: Chi Square | ||

| One Way Anova | ||

| 3.5 | Hypothesis Testing with Non-Normal Data | |

| MannWhitney | ||

| Kruskal Wallis | ||

| Mood’s Median | ||

| Friedman | ||

| 1 Sample Sign | ||

| 1 Sample Wilcoxon | ||

| One and two Sample proportion | ||

| ChiSquared | ||

| Day – 4 | 4 | Improve |

| 4.1 | Root Cause Analysis | |

| 4.2 | Correlation and Linear regression | |

| Correlation | ||

| Scatter Plot/ XY Diagram | ||

| Regression Analysis | ||

| Residuals Analysis | ||

| Multiple Linear Regressions | ||

| Data Transformation, Box, Cox | ||

| 4.3 | Design of Experiments (DOE) | |

| Designed Experiments | ||

| Full Factorial Experiments | ||

| Fractional Factorial Experiments | ||

| 4.4 | Lean Tools and Practices | |

| Lean:5s Visual Factory & Standardized work | ||

| Lean: Kaizen, Kanban & PokaYoke | ||

| 5 | Control | |

| 5.1 | Statistical Process Control (SPC) | |

| Data Collection for SPC | ||

| Control Chart Structure and Rules | ||

| IMR Chart | ||

| XbarR Chart | ||

| XbarS Chart | ||

| NPChart | ||

| PChart | ||

| CChart | ||

| UChart | ||

| CumSum Chart | ||

| EWMA Chart | ||

| 5.2 | Six Sigma Control Plans | |

| Control Plans | ||

| 5.3 | Lean Controls |

Reviews

There are no reviews yet.